To prevent cavitation in your system’s edges, make certain your air bleeds and vacuum relief devices are correctly installed and maintained. These components eliminate trapped air and prevent negative pressure, which cause vapor bubbles to form and collapse. Regular inspections, cleaning, and proper calibration help keep them functioning effectively. Staying on top of venting and pressure control is key; keep watching for signs of cavitation, and you’ll learn simple ways to protect your equipment from damage.

Key Takeaways

- Properly install and regularly maintain air bleeds and vacuum relief devices to prevent trapped air and negative pressure that cause cavitation.

- Ensure vents are clear of clogs and positioned strategically to allow continuous air escape, reducing cavitation risks.

- Monitor system pressure and flow; early signs like noise or surface damage indicate potential cavitation, prompting prompt action.

- Use calibrated vacuum relief devices to automatically manage negative pressures during flow changes, protecting equipment edges.

- Conduct routine inspections and replace worn components to maintain effective venting and prevent cavitation-related damage.

Understanding Cavitation and Its Impact on Equipment

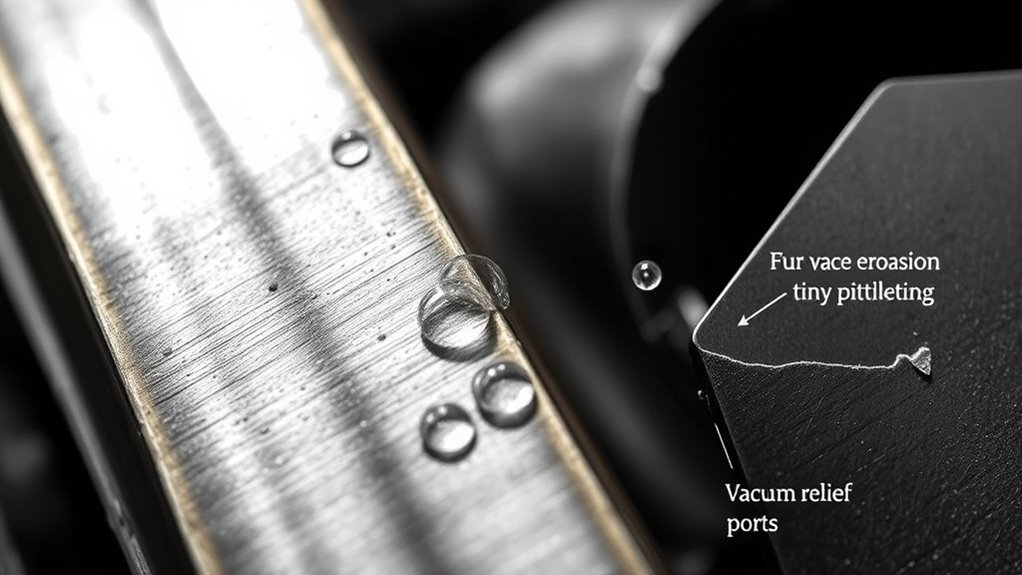

Cavitation occurs when vapor bubbles form in a liquid due to sudden pressure drops, and if left unchecked, it can cause serious damage to your equipment. When this happens, the collapsing bubbles create tiny shockwaves that erode metal surfaces, leading to pitting and eventual failure. You might notice increased noise, vibrations, or a decrease in system efficiency as cavitation worsens. It often occurs in pumps, valves, or other fluid-moving components when flow conditions change abruptly. Cavitation not only shortens equipment lifespan but also results in costly repairs and downtime. Recognizing the signs early helps you prevent severe damage. Proper maintenance, controlling flow rates, and ensuring adequate system pressure are essential steps to minimize cavitation’s harmful effects. Incorporating sound vibrations science can help in diagnosing and mitigating cavitation issues more effectively.

The Function and Importance of Air Bleeds in System Maintenance

Air bleeds play a crucial role in maintaining the efficiency and longevity of your system by removing trapped air and gases. When air pockets accumulate, they can cause uneven flow, reduce heat transfer, and lead to increased wear on components. By releasing these air bubbles, air bleeds ensure fluid moves smoothly through pipes and equipment. This process helps prevent localized pressure drops and minimizes the risk of cavitation, which can damage pumps and valves. Properly functioning air bleeds also improve system stability and reduce energy consumption. Regular maintenance of air bleed valves keeps your system operating at peak performance, reducing unscheduled downtime and costly repairs. Understanding the contrast ratio of your system components can further optimize performance and prevent issues related to image quality or fluid flow. In essence, air bleeds are indispensable for maintaining system integrity, efficiency, and lifespan.

How Vacuum Relief Devices Protect Against Unwanted Pressure Drops

Vacuum relief devices play an essential role in protecting your system from harmful pressure drops that can occur during operation. When fluid levels drop or flow rates change unexpectedly, a vacuum can form, creating negative pressure that stresses pipes and equipment. Without a vacuum relief device, this pressure can cause cavitation, damage, or system failure. These devices automatically open when the vacuum reaches a preset level, allowing air or fluid to enter and equalize the pressure. This prevents the formation of a vacuum that could lead to structural damage or operational inefficiencies. Proper installation and regular checks are key to effective protection. Additionally, understanding fluid dynamics can help optimize the design and placement of vacuum relief devices to better prevent cavitation.

Common Signs of Cavitation and Early Detection Methods

You might notice strange noises coming from your equipment, which can signal cavitation. Surface damage, like pitting or erosion, is another clear indicator that cavitation is occurring. Recognizing these signs early helps prevent costly repairs and keeps your system running smoothly. Additionally, monitoring for AI vulnerabilities that could impact equipment safety is increasingly important as technology advances.

Unusual Noise Indicators

Unusual noises in a system often signal underlying issues like cavitation, which can cause significant damage if left unchecked. You might notice a persistent rattling, banging, or knocking sound during operation. These noises are typically caused by vapor bubbles collapsing violently, creating shockwaves that generate noise. Pay attention to high-pitched squeals or grinding sounds, as they can indicate cavitation near impellers or blades. Early detection involves listening carefully during system operation and noting any irregular sounds. Regularly inspecting for changes in noise levels helps catch cavitation early, preventing costly damage. Additionally, understanding vapor bubble formation can aid in diagnosing the root cause of noise issues. If you hear abnormal noises, don’t ignore them—investigate promptly to identify potential cavitation issues before they escalate. Addressing noise indicators early can save you time, money, and equipment lifespan.

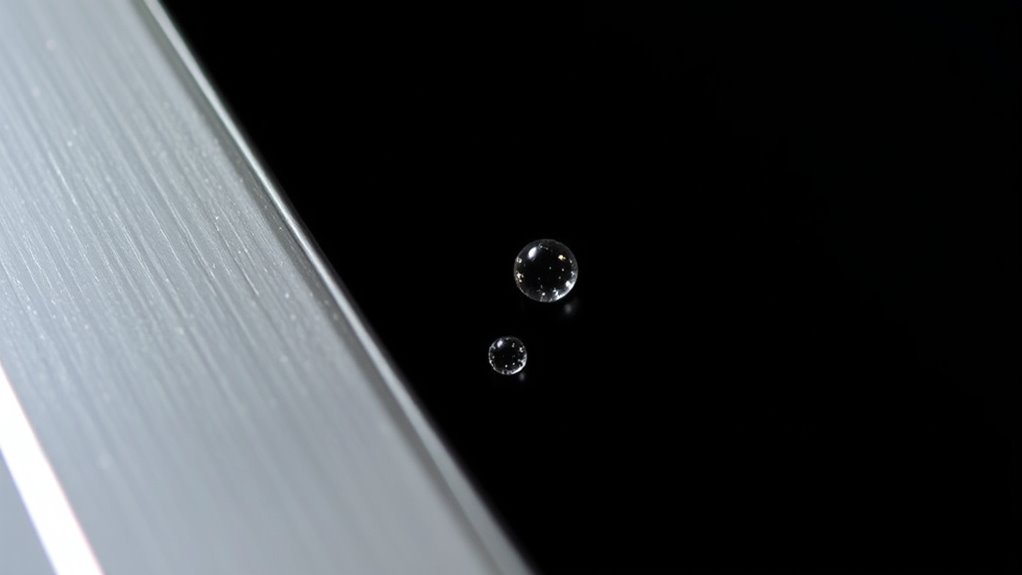

Surface Damage Signs

Surface damage signs are key indicators of cavitation that can help you catch problems early. Look for pitting, erosion, or small craters on the edges of your impellers, blades, or other rotating parts. These surface imperfections often appear after cavitation has started, signaling that vapor bubbles are collapsing near metal surfaces. You might also notice irregular wear patterns or roughness on the surfaces, which can lead to decreased efficiency and increased vibration. Regular visual inspections are essential—check for discoloration, cracks, or material loss. Early detection allows you to address cavitation before it causes costly damage. Pay close attention to these signs and act promptly to prevent further deterioration and extend the lifespan of your equipment. Understanding cavitation mechanisms can help you implement more effective preventative measures.

Proper Installation and Maintenance of Air Bleeds and Vacuum Relief Valves

Proper installation and maintenance of air bleeds and vacuum relief valves are essential to guarantee their reliable operation and prevent system issues. When installing, ensure valves are positioned correctly, with proper orientation and secure fittings to avoid leaks or malfunctions. Regularly inspect for corrosion, dirt, or damage that can impair performance. Clean valves as needed and replace worn or faulty parts promptly. Confirm that settings are calibrated according to manufacturer specifications to maintain proper airflow and pressure relief. Keep a maintenance schedule to check for leaks, blockages, and proper operation. Proper installation and ongoing upkeep help prevent cavitation, reduce system downtime, and extend the lifespan of your equipment. Staying vigilant ensures your system functions smoothly and efficiently. Understanding system flow rate is also crucial when selecting and maintaining these valves to match your water demand and prevent pressure issues.

Preventative Measures to Avoid Cavitation-Related Damage

To prevent cavitation-related damage, you need to focus on proper venting practices and regular system maintenance. Ensuring vents are correctly installed and functioning helps release trapped air and maintain pressure balance. Consistent upkeep keeps your system operating smoothly and reduces the risk of cavitation issues. Additionally, monitoring your system’s lifestyle to identify early signs of imbalance can help address potential problems before they lead to damage.

Proper Venting Practices

Ensuring effective venting is essential to prevent cavitation-related damage in your system. Proper venting removes trapped air and maintains smooth fluid flow, reducing pressure fluctuations. To do this effectively, focus on these practices:

- Place air vents at high points to allow trapped air to escape easily.

- Use automatic air vents that release air without manual intervention.

- Regularly inspect vents for clogs or leaks to guarantee continuous operation.

- Incorporate vertical storage solutions to help identify high points where air may accumulate and facilitate better vent placement.

Visualize air bubbles rising and escaping through dedicated vents, preventing pockets of air from causing pressure drops. Installing vents at strategic locations keeps your system free of air pockets, maintaining ideal flow and pressure. Proper venting minimizes cavitation risk and extends component lifespan, guaranteeing reliable performance. Keep these practices in mind to safeguard your equipment from cavitation-related damage.

Regular System Maintenance

Regular system maintenance is essential for preventing cavitation-related damage and ensuring reliable operation. You should regularly inspect your equipment for signs of wear, corrosion, or blockages that can disrupt flow and cause vacuum issues. Keep air bleeds and vacuum relief valves clean and functioning correctly, replacing faulty parts promptly. Monitoring system pressure and flow rates helps you identify early warning signs of cavitation, enabling quick corrective actions. It’s also wise to verify that venting systems are clear and operating as designed. Conducting system performance tests periodically can help detect issues before they lead to damage. Consistent maintenance reduces the risk of unexpected failures, extends equipment lifespan, and maintains efficient operation. By staying proactive and addressing minor issues before they escalate, you prevent cavitation-related damage and keep your system running smoothly.

Real-World Examples of Cavitation and Lessons Learned

Cavitation incidents in industrial systems often serve as cautionary tales, revealing how seemingly minor issues can escalate into costly damage. For example, a pump running dry caused severe blade erosion, leading to unexpected shutdowns. In another case, improper air venting created vacuum pockets, resulting in pipe bursts. Lastly, a poorly maintained valve allowed air to accumulate, causing cavitation noise and equipment failure. These incidents highlight the importance of vigilant monitoring and preventive measures. To avoid similar pitfalls:

Cavitation risks highlight the need for vigilant monitoring and proactive maintenance to prevent costly industrial damage.

- Regularly inspect and maintain air vents and vacuum relief devices

- Monitor system pressures to detect sudden drops

- Address cavitation signs immediately before damage worsens

Understanding these lessons helps you prevent costly repairs and extend equipment lifespan, ensuring your system runs smoothly and safely.

Frequently Asked Questions

How Do Temperature Fluctuations Influence Cavitation Risk?

Temperature fluctuations can considerably increase your cavitation risk because they cause changes in fluid density and vapor pressure. When temperatures rise, vapor pressure goes up, making it easier for bubbles to form and collapse, damaging your equipment. Conversely, dropping temperatures lower vapor pressure, but rapid fluctuations can still create unstable conditions. To minimize cavitation, you should maintain consistent temperatures and monitor your system closely during temperature changes.

Are There Specific Industries More Prone to Cavitation Issues?

You might think cavitation only affects certain industries, but it can happen anywhere with fluid systems and pressure changes. Industries like marine, hydraulic, power generation, and chemical processing are especially prone due to high pressures and rapid flow variations. Even if you believe your system’s safe, neglecting proper air bleed and vacuum relief can cause cavitation damage. Stay vigilant, maintain your equipment, and implement safeguards to prevent costly failures.

Can Improper Fluid Viscosity Cause Cavitation Problems?

Yes, improper fluid viscosity can cause cavitation problems. If the fluid’s viscosity is too low, it may vaporize easily under pressure changes, leading to cavitation. Conversely, if it’s too high, it can create excessive resistance, leading to localized pressure drops and vapor bubbles forming. To prevent cavitation, guarantee you’re using the correct viscosity fluid recommended for your equipment, maintaining ideal flow conditions and avoiding abrupt pressure fluctuations.

What Materials Are Best Suited for Cavitation-Resistant Components?

A stitch in time saves nine, so choosing the right materials is vital. For cavitation-resistant components, you should opt for metals like stainless steel, bronze, or certain alloys such as inconel. These materials withstand high stress and erosion better than plastics or softer metals. Additionally, ceramic composites can be highly effective. Selecting durable, corrosion-resistant materials helps prevent cavitation damage and extends the lifespan of your equipment.

How Does System Design Affect the Likelihood of Cavitation Occurrence?

Your system design influences cavitation risk considerably. If you minimize sudden pressure drops, keep flow velocities within safe limits, and guarantee smooth, streamlined pathways, you reduce cavitation chances. Proper placement of air vents and vacuum relief valves helps manage pressure fluctuations. Additionally, avoiding sharp bends and obstructions maintains steady flow, preventing vapor bubble formation. Thoughtful design choices help your system operate efficiently while avoiding cavitation damage.

Conclusion

So, next time you ignore those tiny air bleeds or neglect your vacuum relief valves, remember—they’re not just optional extras. Cavitation might seem harmless until it wrecks your equipment, proving that overlooking simple maintenance can turn into a costly lesson. Ironically, the very devices meant to protect your system could be the first to fail if you dismiss their importance. Stay vigilant—your equipment’s survival depends on it.