Switching to sustainable materials in HVAC systems allows you to choose recyclable components like eco-friendly insulation and refrigerants with low global warming potential, reducing environmental harm. These options improve energy efficiency, cut down on waste, and support healthier indoor air quality. By adopting eco-conscious materials, you can lower your carbon footprint and enjoy long-term savings. Keep exploring to discover how these sustainable choices can make a real difference in your building’s impact.

Key Takeaways

- Recyclable refrigerants like HFOs, propane, and isobutane reduce environmental impact and support reuse at end-of-life.

- Eco-friendly insulation materials such as cellulose, sheep’s wool, and recycled cotton improve indoor air quality and energy efficiency.

- Sustainable HVAC components lower greenhouse gas emissions and contribute to climate change mitigation efforts.

- Use of environmentally friendly materials can qualify for government incentives, lowering long-term project costs.

- Incorporating recyclable and natural materials promotes healthier indoor environments and reduces overall ecological footprint.

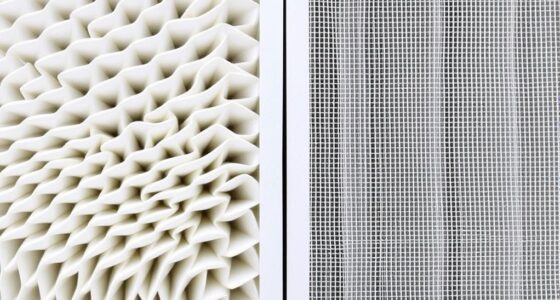

As the demand for eco-friendly building solutions grows, incorporating sustainable materials into HVAC systems has become essential. You can markedly reduce your environmental footprint by choosing components that prioritize sustainability without sacrificing performance. For example, eco-friendly insulation options are increasingly popular. Unlike traditional fiberglass or foam insulations, eco friendly insulation is made from natural or recycled materials, such as cellulose, sheep’s wool, or recycled cotton. These materials not only insulate effectively but also minimize off-gassing and reduce the release of harmful volatile organic compounds (VOCs) into your indoor environment. By selecting sustainable insulation, you contribute to healthier indoor air quality and lower your building’s overall environmental impact.

Recyclable refrigerants are another critical component in making HVAC systems more sustainable. Traditional refrigerants, like hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs), have high global warming potentials and can harm the ozone layer if leaked or improperly disposed of. In contrast, recyclable refrigerants are designed to be reused and recycled at the end of their life cycle, considerably reducing waste and environmental harm. These refrigerants, such as hydrofluoroolefins (HFOs) or natural options like propane and isobutane, have low global warming potential and are more environmentally benign. Choosing HVAC systems that use recyclable refrigerants helps lower greenhouse gas emissions and aligns your building with sustainability goals.

Integrating these sustainable materials into your HVAC setup isn’t just about compliance or market trends; it’s about actively reducing your ecological footprint. Eco friendly insulation and recyclable refrigerants work together to improve energy efficiency, which means less energy consumption and lower utility bills over time. They also help preserve natural resources by minimizing waste and encouraging the reuse of materials. When you opt for these solutions, you’re making a conscious decision to support environmental health and promote a greener future.

Furthermore, these sustainable choices often come with long-term cost savings and potential incentives. Many governments and local authorities offer rebates or tax credits for installing eco-friendly HVAC components, making your investment even more worthwhile. Plus, healthier indoor environments result from reduced exposure to harmful chemicals and improved air quality, benefiting everyone who uses the space. Ultimately, by prioritizing eco friendly insulation and recyclable refrigerants, you’re not only enhancing your building’s sustainability but also contributing to a broader effort to combat climate change and conserve our planet’s resources.

Frequently Asked Questions

How Do Recyclable HVAC Components Affect Overall System Efficiency?

Recyclable HVAC components boost overall system efficiency by encouraging innovative recyclable component design, which often leads to lighter and more durable parts. These designs optimize energy use and reduce waste, enhancing environmental performance metrics. You’ll notice improved operational performance, lower energy consumption, and a smaller carbon footprint. By choosing systems with recyclable components, you actively support sustainable practices while maintaining high efficiency standards, ultimately benefiting both your environment and your energy bills.

What Are the Cost Differences Between Traditional and Sustainable HVAC Materials?

You’ll find that sustainable HVAC materials often have higher manufacturing costs upfront due to advanced technology and material durability. However, over time, these costs can be offset by savings on energy efficiency and reduced waste disposal. Traditional materials might be cheaper initially, but they can lead to higher maintenance and replacement expenses. Ultimately, investing in sustainable materials balances initial costs with long-term environmental benefits and system longevity.

How Long Do Eco-Friendly HVAC Components Typically Last?

You might think eco-friendly HVAC components don’t last as long, but they actually offer impressive lifecycle longevity. Typically, these sustainable materials have comparable or even greater material durability than traditional options, often lasting 10 to 15 years or more with proper maintenance. By choosing high-quality recyclable components, you guarantee your system stays efficient longer, reducing replacement costs and environmental impact. So, durability isn’t sacrificed for sustainability—it’s enhanced.

Are There Government Incentives for Using Recyclable HVAC Materials?

Yes, there are government incentives for using recyclable HVAC materials. You can access government grants and policy incentives designed to encourage eco-friendly practices. These programs aim to reduce environmental impact by making sustainable options more affordable. By leveraging these incentives, you can lower your costs and support greener building efforts. Always check with local or federal agencies to find current opportunities and eligibility requirements for recyclable HVAC components.

What Challenges Exist in Sourcing Sustainable Materials for HVAC Manufacturing?

You face challenges sourcing sustainable materials for HVAC manufacturing due to supply chain issues and raw material scarcity. Limited availability of eco-friendly components can delay production and increase costs. You might also encounter difficulty finding suppliers committed to sustainability standards, which complicates your sourcing process. To overcome these hurdles, you’ll need to build strong supplier relationships, explore alternative eco-friendly materials, and stay flexible with your procurement strategies.

Conclusion

Switching to sustainable HVAC materials might seem costly upfront, but it pays off in the long run through energy savings and reduced environmental impact. Don’t let concerns about initial expenses hold you back—investing in recyclable components guarantees a healthier planet and lower operating costs over time. By choosing eco-friendly options, you help create a sustainable future. Remember, small changes today can make a big difference tomorrow—so why not start with your HVAC system?