To prevent and remove calcium scale on the weir, regularly monitor your water’s hardness and pH levels, and use chemical inhibitors or water softeners to reduce mineral buildup. Mechanical cleaning with scrapers or brushes can effectively remove existing deposits, while consistent maintenance prevents further accumulation. Ensuring stable water temperature and flow also helps. For more detailed strategies, explore proven methods to keep your weir clean and efficient.

Key Takeaways

- Regularly inspect the weir for early signs of calcium deposits and monitor water hardness and pH levels.

- Use chemical scale inhibitors and water softeners to prevent calcium crystallization on the weir surface.

- Implement mechanical cleaning methods, such as manual scraping or brushing, to remove existing calcium buildup.

- Maintain consistent water temperature and flow rates to reduce mineral precipitation and scale formation.

- Establish routine maintenance and monitoring schedules to prevent excessive calcium scale accumulation.

Understanding Calcium Scale Formation on Weirs

Calcium scale forms on weirs when calcium-rich water interacts with surfaces, causing minerals to precipitate out of solution. When water containing dissolved calcium and carbonate ions flows over a weir, changes in temperature, pH, or flow rate can reduce the water’s ability to keep minerals dissolved. As a result, calcium carbonate crystals begin to form and settle on the surface. Over time, these deposits grow thicker, creating a hard, chalky layer. This buildup can obstruct flow, reduce measurement accuracy, and increase maintenance needs. Understanding this process helps you recognize that calcium scale isn’t caused by dirt or grime but by the natural chemistry of calcium and carbonate ions in the water. Properly addressing the conditions that promote mineral precipitation is key to preventing excessive scale formation. Monitoring water quality parameters such as pH levels can help detect early signs of scale formation and enable preventative action.

Factors Contributing to Calcium Scale Buildup

Your water’s hardness levels directly influence calcium scale buildup on the weir, with higher mineral content increasing the risk. Temperature fluctuations also play a role, as changes can accelerate or slow down scale formation. Additionally, variations in chemical composition can affect how quickly calcium deposits develop on the surface. Proper venting and maintenance of the system can help mitigate some of these issues and prevent excessive buildup.

Water Hardness Levels

Have you ever wondered why some water causes more scale buildup than others? It all comes down to water hardness levels. Hard water contains higher concentrations of dissolved minerals like calcium and magnesium, which settle as scale when heated or exposed to air. The harder the water, the more likely you’ll see calcium deposits forming on your weir. To visualize, consider this table:

| Water Type | Mineral Content | Scale Potential |

|---|---|---|

| Soft Water | Low minerals | Minimal/none |

| Moderately Hard | Moderate minerals | Some buildup |

| Hard Water | High minerals | Significant buildup |

| Very Hard | Very high minerals | Rapid, thick deposits |

Your water’s mineral level directly impacts how quickly calcium scale develops. Additionally, understanding water hardness can help you implement effective scale prevention measures to protect your equipment.

Temperature Fluctuations Impact

Temperature fluctuations substantially influence calcium scale buildup on weirs. When water temperature changes, it affects the solubility of calcium carbonate, causing it to precipitate more rapidly during cooler periods. As water cools, calcium carbonate becomes less soluble, leading to increased scale formation on the weir surface. Conversely, during warmer periods, some of the accumulated deposits may partially dissolve, but frequent temperature swings hinder complete removal. Rapid or frequent temperature shifts accelerate the cycle of deposition and partial dissolution, resulting in thicker, more stubborn scale buildup over time. Maintaining stable water temperatures minimizes these fluctuations, reducing the likelihood of calcium scale formation. By controlling temperature variations, you can considerably lessen the rate at which calcium deposits accumulate on your weir, simplifying maintenance and improving system efficiency.

Chemical Composition Variations

Variations in chemical composition within water sources substantially contribute to calcium scale buildup on weirs. When water contains fluctuating levels of calcium, magnesium, bicarbonates, and other minerals, scaling becomes more likely. These shifts can result from changes in source water, seasonal variations, or industrial discharges. Such fluctuations influence the saturation levels of minerals, increasing the likelihood of calcium carbonate precipitation. Understanding these variations helps you anticipate scale formation and develop more effective prevention strategies. Additionally, monitoring water quality parameters can provide early warnings of imminent scaling issues.

Signs and Detecting Calcium Scale Accumulation

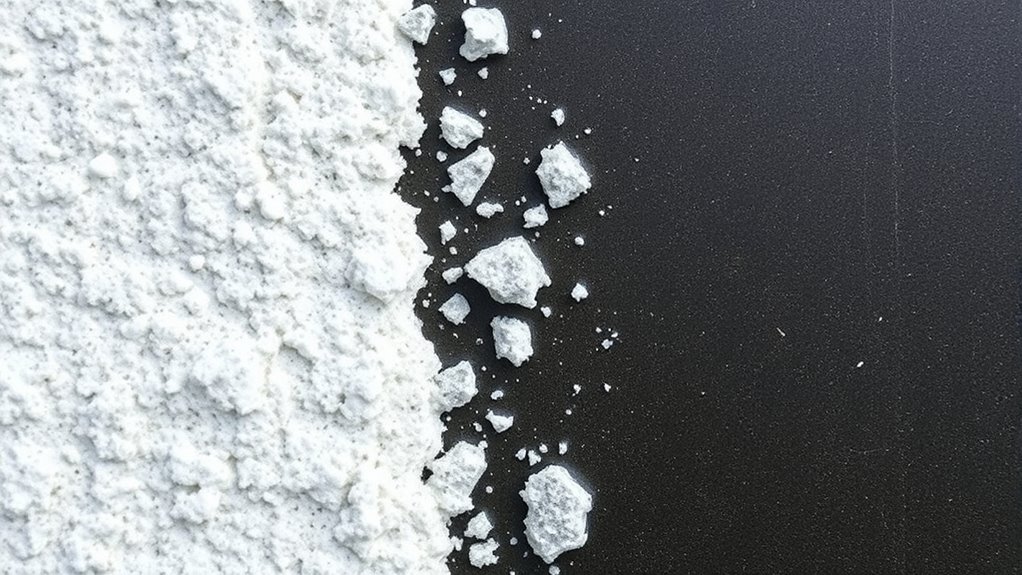

You can often identify calcium scale buildup on the weir by visual cues such as white, chalky deposits or a crusty layer forming along the water flow surface. These deposits tend to appear as irregular patches or a consistent coating, especially in areas where water flow slows. You might notice a rough texture or a dull appearance compared to the smooth, clean surface of a healthy weir. Additionally, calcium scale can cause a decrease in water flow efficiency, leading to potential operational issues. In some cases, mineral deposits may flake off or create a gritty residue. Regular inspection is key—look for changes in water clarity or flow patterns, and keep an eye out for visible buildup that suggests calcium deposits are forming or accumulating over time. Recognizing early signs of scale formation can help prevent more severe buildup and maintain optimal water flow.

Preventive Strategies for Calcium Scale Development

Implementing effective preventive strategies is essential to minimize calcium scale development on the weir. By controlling water chemistry and flow conditions, you can considerably reduce scale formation. Start by regularly monitoring water hardness and pH levels to keep them within ideal ranges. Additionally, consider adjusting flow rates to prevent stagnation, which encourages mineral buildup. Implementing filtration systems can remove calcium and other minerals before they deposit. Finally, maintaining consistent water temperature prevents supersaturation that leads to scale formation. These strategies help you create an environment less conducive to calcium deposit buildup, extending equipment life and ensuring smoother operation. Regular water quality testing and monitoring, adjusting flow rates to prevent stagnation, installing filtration to reduce mineral load, maintaining stable water temperature, and understanding celebrity lifestyle insights can further optimize your preventive measures.

Chemical Treatments to Minimize Scale Formation

Chemical treatments offer an effective approach to reducing calcium scale formation on the weir by altering water chemistry. You can add scale inhibitors, which interfere with calcium carbonate crystallization, preventing buildup. These chemicals work by stabilizing calcium ions, making it harder for scale to form. Additionally, understanding the importance of contrast ratio can help in optimizing visual clarity of displays used to monitor water quality and treatment effectiveness.

Mechanical Methods for Scale Removal

Mechanical methods for scale removal often involve manual scraping techniques and specialized cleaning equipment. You can physically remove calcium deposits with scrapers or brushes, which provides immediate results. Using appropriate tools and machines helps guarantee thorough cleaning and minimizes damage to the weir surface. Incorporating self-watering plant pots into maintenance routines can also help prevent scale buildup by maintaining consistent moisture levels.

Manual Scraping Techniques

Manual scraping is a straightforward and effective method for removing calcium scale from the weir. You need a sturdy scraper or putty knife to carefully chip away the buildup without damaging the surface. This technique allows precise control, especially on localized areas of heavy accumulation. To guarantee safety and efficiency, consider the following:

- Wear protective gloves and eye goggles to prevent injury from debris.

- Use a firm, consistent pressure to loosen the scale without gouging the material.

- Work in a well-ventilated area to avoid inhaling dust particles.

- Regularly clean your tools to maintain their effectiveness and prevent spreading scale residues.

- Additionally, understanding the divorce process in your state can help you manage other related legal or administrative issues effectively.

Manual scraping can be done periodically for maintenance or as a preliminary step before more intensive cleaning methods. Proper technique minimizes damage and prolongs the weir’s lifespan.

Mechanical Cleaning Equipment

When dealing with heavy calcium scale buildup on the weir, specialized mechanical cleaning equipment can make the job more efficient and less labor-intensive. Power tools like rotary brushes, scrapers, and high-pressure water jets can quickly remove stubborn deposits. These tools reach difficult spots and reduce manual effort, saving time and improving safety. Choose equipment based on scale thickness and weir material. For example, rotary brushes are ideal for light to moderate buildup, while pressure washers tackle thicker deposits effectively. Use the following table to compare options:

| Equipment Type | Suitability | Benefits |

|---|---|---|

| Rotary Brush | Light to moderate scale | Quick, thorough cleaning |

| High-Pressure Water Jet | Heavy scale | Deep cleaning, fast |

| Mechanical Scraper | Moderate to heavy scale | Precise, controlled removal |

Additionally, selecting the right tuning techniques can optimize the performance of your vehicle after maintenance.

Using Water Conditioners and Softening Techniques

Using water conditioners and softening techniques is an effective way to prevent calcium scale buildup on the weir. These methods reduce the hardness of water, decreasing calcium and magnesium concentrations that cause scale formation. Water softeners, such as ion exchange systems, replace calcium ions with sodium, preventing deposits. Alternatively, chemical water conditioners alter mineral properties, inhibiting crystal growth. Proper application guarantees longer-lasting equipment and cleaner weirs. To maximize effectiveness, consider:

Water conditioners and softening techniques effectively prevent calcium scale buildup on weirs.

- Installing an ion exchange softening unit

- Using polyphosphate dosing systems

- Regularly monitoring water hardness levels

- Combining chemical conditioners with filtration systems

Implementing these strategies helps maintain smooth operation, reduces maintenance costs, and prolongs the lifespan of your weir, making scale buildup less of a concern.

Regular Maintenance and Monitoring Practices

Regular maintenance and monitoring are essential to prevent calcium scale buildup on the weir. You should inspect the weir regularly for signs of scale accumulation, such as reduced flow or visible deposits. Establish a routine cleaning schedule based on your system’s water quality and usage levels. Keep detailed records of inspections, cleaning dates, and any issues encountered. Monitoring water parameters like hardness and pH helps you identify early signs of scaling. Installing sensors or gauges can provide real-time data, allowing you to react promptly. Consistent oversight ensures you catch problems before they worsen, saving you time and cost in repairs or scale removal. By staying proactive with maintenance and monitoring, you considerably reduce the risk of calcium scale impairing your system’s performance.

Choosing the Right Products and Technologies for Scale Control

Choosing the right products and technologies for scale control can considerably improve your ability to prevent calcium buildup on the weir. Selecting effective solutions depends on understanding your water chemistry, system design, and operational needs. Modern options include chemical treatments, automated dosing systems, water softeners, and scale inhibitors. These tools help inhibit calcium crystallization and reduce deposits before they form. Consider the following:

Effective scale control combines water chemistry knowledge with modern treatment solutions to prevent calcium buildup.

- Chemical Scale Inhibitors: Prevent calcium from crystallizing on surfaces.

- Automated Dosing Pumps: Ensure consistent application of treatment chemicals.

- Water Softening Equipment: Remove calcium ions before they cause scale.

- Real-Time Monitoring Technologies: Detect early signs of scale formation for prompt action.

Choosing the appropriate combination of these products enhances efficiency, minimizes maintenance, and prolongs equipment lifespan.

Frequently Asked Questions

How Often Should I Inspect My Weir for Calcium Scale?

You should inspect your weir for calcium scale weekly or more often if your water has high mineral content. Regular inspections help you catch buildup early, preventing operational issues. Look for visible white deposits or rough surfaces on the weir. If you notice significant scale, clean it promptly to maintain proper flow and measurement accuracy. Consistent monitoring guarantees your system runs efficiently and reduces the risk of costly repairs later.

Are There Eco-Friendly Options to Prevent Calcium Scale Buildup?

Yes, you can use eco-friendly options like adjusting water chemistry, such as reducing calcium levels with natural water treatments or using biodegradable scale inhibitors. Regularly cleaning the weir with eco-safe descaling solutions also helps prevent buildup. Additionally, installing a water softener that uses salt-free technology can reduce calcium deposits without harming the environment. These approaches keep your system efficient while being environmentally conscious.

Can Calcium Scale Damage the Structural Integrity of the Weir?

Think of calcium scale as a silent invader gradually wearing down your weir’s strength. Yes, it can damage the structural integrity if left untreated, as the buildup causes stress and corrosion over time. You need to regularly inspect and clean the weir, using eco-friendly removal methods when possible. Addressing calcium scale early keeps your weir resilient, preventing costly repairs and ensuring it continues to serve its purpose effectively.

What Is the Most Cost-Effective Method for Large-Scale Scale Removal?

You should consider using chemical descaling agents like acids or specialized detergents, as they’re often the most cost-effective for large-scale removal. These solutions can efficiently break down calcium deposits, reducing labor and equipment costs. Make sure to follow safety protocols and manufacturer instructions to avoid damage. Regular maintenance using these chemicals can also prevent heavy buildup, saving you money in the long run.

How Does Water Temperature Influence Calcium Scale Formation?

Water temperature considerably influences calcium scale formation. When water gets warmer, calcium carbonate becomes less soluble, increasing the likelihood of scale buildup on surfaces like the weir. Higher temperatures accelerate chemical reactions, causing calcium deposits to form more quickly and adhere more firmly. To minimize scale formation, you should keep water temperatures moderate and consider using antiscalants or water treatment systems that reduce calcium precipitation at elevated temperatures.

Conclusion

By understanding how calcium scale forms and applying effective prevention and removal methods, you can guarantee your weir functions smoothly—much like a well-tuned orchestra. Regular maintenance and smart water conditioning are your symphony’s conductor, preventing buildup before it starts. Stay vigilant, and you’ll keep calcium scale at bay, preserving your system’s clarity and efficiency, much like a pristine lake untouched by time. Ultimately, your proactive approach keeps the flow pure and uninterrupted.