To make certain your waterproofing system lasts, choose high-quality membranes suited to your environment, like PVC or EPDM, and apply them correctly to prevent leaks. Combine durable mortars with waterproof additives and select flexible sealants that can handle movement and temperature changes. Proper installation and ongoing maintenance are key to long-term protection. If you want to discover proven techniques and best practices for building a reliable waterproofing stack, keep exploring.

Key Takeaways

- Choose compatible, durable membranes, mortars, and sealants resistant to environmental stresses for long-lasting waterproofing.

- Ensure proper surface preparation and correct application techniques to optimize adhesion and system integrity.

- Incorporate layered protection with membranes, mortars, and sealants for redundancy and enhanced durability.

- Select flexible sealants that accommodate structural movement and prevent cracks over time.

- Regular inspection and maintenance help identify issues early, extending the waterproofing system’s lifespan.

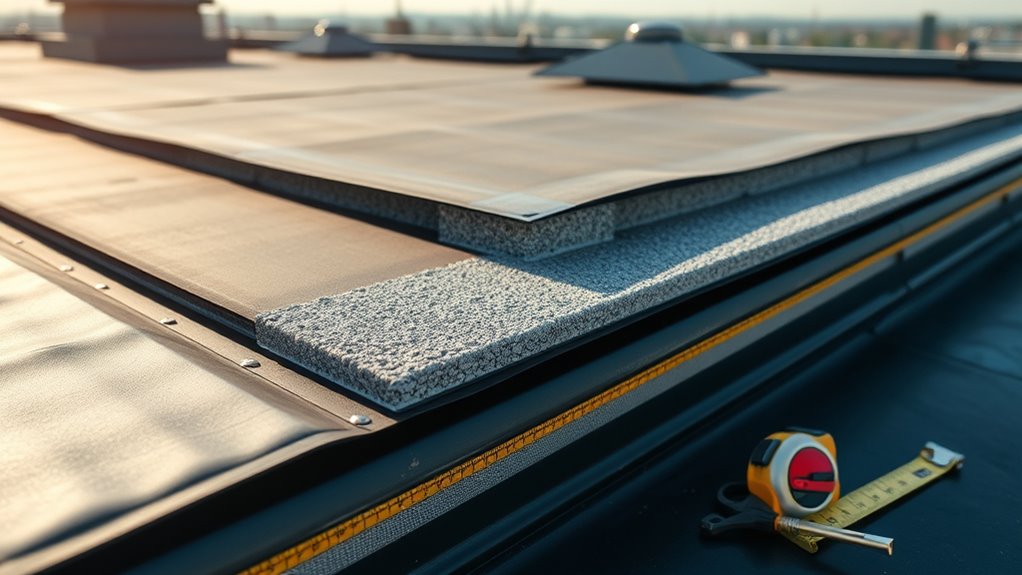

Understanding Waterproofing Membranes and Their Types

Waterproofing membranes are essential materials used to prevent water infiltration in various structures, ensuring durability and protection. You’ll find these membranes made from different materials, each suited for specific applications. Bituminous membranes, for example, are bitumen-based and flexible, ideal for roofs and foundations. PVC membranes are synthetic and highly durable, often used in underground structures and basements. TPO membranes combine the benefits of PVC and EPDM, offering UV resistance and flexibility. EPDM membranes are rubber-based, excellent for roof waterproofing due to their resilience to weathering. Liquid-applied membranes create seamless, flexible coatings that conform to complex surfaces. Choosing the right type depends on your project’s requirements, environment, and longevity needs. Understanding these options helps you select the best membrane for lasting waterproof protection. Low-carb ingredients are often used to enhance the durability of waterproofing products, especially in environmentally demanding applications.

Selecting Durable Waterproofing Mortars for Long-Term Protection

When choosing waterproofing mortars, you need to consider their material strength and how well they bond with different surfaces. Proper application techniques are essential to guarantee long-lasting protection. By paying attention to these factors, you can select a mortar that offers durability and reliable performance over time. For optimal results, selecting products that have been tested for high suction power and compatibility with various surfaces can significantly improve the longevity of your waterproofing system.

Material Composition and Strength

Choosing the right waterproofing mortar begins with understanding its material composition and strength. You should look for mortars with durable components that resist environmental stress. Key factors include:

- Cement-based binders: They provide strength and adhesion essential for long-lasting protection.

- Additives: Waterproofing agents like polymers or latex improve flexibility and water resistance.

- Aggregate quality: Fine, well-graded aggregates enhance durability and reduce permeability.

A strong mortar withstands cracks, shifting substrates, and moisture infiltration. Its composition determines how well it performs over time. To ensure longevity, select a mortar with a balanced mix that offers both compressive strength and flexibility. Remember, the right material composition directly influences its ability to maintain waterproofing integrity long-term. Smart home technology can also be incorporated into waterproofing systems to monitor moisture levels and detect leaks early, further enhancing durability.

Compatibility With Surfaces

Selecting a waterproofing mortar that is compatible with your surfaces is essential for guaranteeing long-term durability and effectiveness. You need to choose a mortar that bonds well with the substrate, whether it’s concrete, brick, or stone. Incompatible mortars can cause delamination, cracking, or reduced adhesion, compromising the waterproofing system. Consider the porosity, texture, and chemical composition of your surfaces when selecting a mortar. For example, highly porous surfaces may require a primer or a mortar with added bonding agents. Additionally, check the mortar’s pH and chemical resistance to ensure it won’t degrade or react adversely over time. Proper compatibility minimizes risks of failure, extends the lifespan of your waterproofing, and guarantees that your surfaces stay protected against water ingress for the long haul. Incorporating vertical storage solutions can also help in organizing your workspace, making it easier to access and apply the appropriate materials for each surface type.

Application Techniques and Durability

Applying waterproofing mortar correctly is essential to guarantee long-lasting protection. Proper techniques ensure the mortar bonds well and resists environmental stresses. First, always prepare the surface thoroughly by cleaning and priming it to enhance adhesion. Second, apply the mortar in consistent, even layers, avoiding gaps or thin spots that compromise durability. Third, follow the manufacturer’s recommended curing time; rushing this step weakens the waterproof barrier. To maximize durability, choose mortars with high-quality binders and additives designed for long-term exposure. Regular inspections and maintenance also play a vital role in extending lifespan. Additionally, selecting the right waterproofing mortar with advanced formulations can significantly improve resistance to water penetration. By following these application techniques, you ensure your waterproofing system remains effective, protecting your structure from water ingress for years to come.

The Role of Sealants in Creating a Watertight Barrier

Sealants must be flexible enough to accommodate building movement without cracking. They also need to be compatible with different materials to guarantee a seamless, watertight seal. Understanding these points helps you choose the right sealant for long-lasting waterproofing. Additionally, selecting sealants with flexible gym hours can help ensure consistent application and maintenance in various environments.

Sealant Flexibility and Movement

Because buildings and structures expand and contract with temperature changes and shifting loads, sealant flexibility is essential for maintaining a watertight barrier. Flexible sealants accommodate these movements without cracking or losing adhesion. To guarantee proper performance, consider these key factors:

- Material Compatibility: Choose sealants compatible with surrounding materials to prevent deterioration.

- Elongation Capacity: Select sealants with high elongation percentages to handle significant movement.

- Application Technique: Proper application ensures the sealant bonds well and remains flexible over time.

Compatibility With Building Materials

Ensuring compatibility between sealants and building materials is crucial for creating an effective watertight barrier. If sealants don’t bond properly or degrade over time, leaks can develop. You need to select sealants that match the specific substrates, such as concrete, metal, or plastic. Compatibility prevents issues like cracking, adhesion failure, or chemical reactions that weaken the seal. Use this table to understand material interactions:

| Material Type | Compatible Sealant Types |

|---|---|

| Concrete, Masonry | Polyurethane, Silicone |

| Metal | Hybrid, Polyurethane |

| Plastic | Acrylic, Silicone |

Choosing the right combination ensures durability, longevity, and a reliable waterproof barrier. For instance, selecting the appropriate electric dirt bikes sealant can help maintain the integrity of the waterproofing system under various conditions.

Combining Materials for a Robust Waterproofing System

Combining different materials is essential for creating a waterproofing system that is both effective and durable. When you select the right mix, you improve overall performance and extend lifespan. To do this successfully, consider these key principles:

Combining materials enhances waterproofing effectiveness and longevity through synergy, compatibility, and layered protection.

- Synergy: Ensure materials complement each other, enhancing waterproofing without gaps or weak points.

- Compatibility: Use components that adhere well together, preventing delamination or chemical reactions.

- Layering: Build multiple protective barriers, so if one fails, others continue to safeguard your structure.

- Material selection: Incorporate water-resistant textiles such as specialized membranes and sealants to reinforce the system’s integrity.

Factors to Consider When Choosing Waterproofing Components

When selecting waterproofing components, you need to take into account several critical factors to guarantee long-lasting protection. First, consider the material’s compatibility with your substrate and other system elements to prevent bonding issues. Durability is essential; choose membranes, mortars, and sealants that withstand environmental stresses like UV exposure, temperature fluctuations, and chemical exposure. Flexibility is also crucial, especially in areas prone to movement or settling, to avoid cracks and failures. Additionally, assess the application method—some materials require specific tools or conditions for proper installation. Cost-effectiveness matters too, but never sacrifice quality for lower prices, as subpar materials can lead to costly repairs later. Finally, review manufacturer specifications and warranties to ensure the components meet your project’s durability and performance standards. Incorporating proper surface preparation can significantly improve the longevity and effectiveness of waterproofing solutions.

Installation Best Practices for Longevity and Effectiveness

Proper installation of waterproofing components is key to achieving long-lasting protection. To guarantee effectiveness, focus on these best practices:

- Prepare surfaces thoroughly—clean, dry, and free of debris to promote strong adhesion.

- Follow manufacturer instructions precisely—use recommended tools, materials, and techniques.

- Ensure proper overlaps and seals—avoid gaps or weak points where water could penetrate.

- Understand the importance of transparent disclosure—being aware of affiliate relationships can help consumers make informed decisions about products and installation methods.

Maintenance and Inspection Tips to Ensure Lasting Waterproofing

Regular maintenance and inspections are essential to keep your waterproofing system effective over time. You should routinely check for signs of damage, such as cracks, blisters, or areas where the membrane or sealant appears compromised. Keep an eye out for water stains, mold, or peeling paint, which can indicate leaks. Clean gutters and drains to prevent water buildup that could stress the waterproofing layers. Inspect joints, seams, and penetrations closely, ensuring they remain sealed and intact. Address minor issues promptly to prevent them from worsening. Use a flashlight to examine hidden or hard-to-reach areas. Regularly scheduled inspections, combined with timely repairs, extend the lifespan of your waterproofing system and protect your property from water damage.

Frequently Asked Questions

How Do Environmental Conditions Affect Waterproofing Material Performance?

Environmental conditions greatly impact waterproofing material performance. You might notice that extreme temperatures cause materials to expand or contract, leading to cracks or gaps. Excess moisture can weaken sealants, making them less effective, while UV exposure from sunlight can degrade membranes over time. To guarantee longevity, you should choose materials suited for your specific climate, apply them correctly, and perform regular inspections to catch any issues early.

What Are Common Causes of Waterproofing System Failures?

Did you know that failure causes account for over 60% of waterproofing issues? You might face system failures due to poor installation, inadequate surface preparation, or using incompatible materials. Environmental factors like UV exposure, temperature fluctuations, and moisture infiltration can also weaken waterproofing. To prevent failure, guarantee proper application, choose suitable materials, and regularly inspect your system for early signs of damage.

Can Waterproofing Membranes Be Repaired After Damage?

Yes, waterproofing membranes can be repaired after damage. You should clean the damaged area thoroughly to remove dirt, debris, and any loose material. Then, apply a compatible patch or sealant specifically designed for the membrane type. Make sure to follow manufacturer instructions for proper adhesion and curing. Proper repair can restore the membrane’s waterproofing ability, extending its lifespan and preventing further water intrusion.

How Long Do Waterproofing Sealants Typically Last?

You get what you pay for, and sealants are no exception. Typically, waterproofing sealants last between 5 to 10 years, depending on the product quality, exposure to weather, and maintenance. Proper application and regular inspections can extend their lifespan. Keep in mind, though, that no sealant is everlasting; over time, it may need touch-ups or replacement to keep your structure watertight.

Are There Eco-Friendly Waterproofing Options Available?

Yes, there are eco-friendly waterproofing options available. You can choose products made from natural or recycled materials, such as plant-based sealants or biodegradable membranes. These options often have lower VOC emissions and are safer for the environment and your health. When selecting eco-friendly waterproofing, look for certifications like Green Seal or LEED, and consult with suppliers to guarantee the products meet sustainability standards without compromising durability.

Conclusion

Think of your waterproofing system like a sturdy shield—when you choose the right membranes, mortars, and sealants, and install them properly, it’ll stand strong for years. Regular inspections are your secret weapon, catching issues before they become big problems. With careful maintenance, your waterproofing is as reliable as a trusted friend, keeping water out and peace of mind in. Invest in quality today, and enjoy a leak-free tomorrow.