When plumbing an edge loop, you need to carefully select pipe sizes that balance flow rate and pressure loss, avoiding undersized pipes that cause turbulence and drops. Manage head loss by choosing smoother pipe materials and maintaining proper flow velocities. Place valves strategically for flow control and system safety, ensuring they’re accessible for maintenance. For ideal performance, focus on clean topology and proper layout. Keep exploring these principles to master efficient piping system design.

Key Takeaways

- Proper pipe sizing balances flow efficiency, pressure maintenance, and cost, preventing issues like head loss and turbulence.

- Selecting pipe materials with smooth surfaces reduces friction and head loss, improving system performance.

- Strategic valve placement near fixtures and at flow control points ensures even distribution and easier maintenance.

- Regularly monitor flow rates and pressure to identify imbalances and optimize pipe diameters and valve settings.

- Maintaining clean, organized edge loops and proper topology minimizes flow disruptions and head loss in plumbing systems.

Understanding the Role of Pipe Sizes in Plumbing Systems

Choosing the right pipe sizes is essential for ensuring efficient water flow and maintaining proper pressure throughout your plumbing system. When pipes are too small, water flow slows down, increasing pressure loss and reducing performance. Larger pipes can improve flow but may be more costly and difficult to install. Proper sizing balances these factors, ensuring enough volume without unnecessary expense. Pipe diameter directly impacts flow rate; bigger pipes allow more water to pass through quickly, while smaller pipes restrict flow. Additionally, correct sizing helps prevent issues like water hammer or pressure drops that can damage fixtures. Understanding how pipe sizes influence flow helps you design a reliable, efficient plumbing system that delivers water where you need it without wasting resources. Using appropriate filtration and pump protection ensures long-term pump performance and prevents clogs that could impair flow.

Calculating and Managing Head Loss for Efficient Flow

To guarantee efficient flow, you need to accurately calculate head loss, which depends on factors like the friction factor and pipe material. Understanding how these elements influence pressure drop helps you optimize system design. By managing head loss effectively, you can improve flow and reduce energy costs in your plumbing setup. Incorporating filter maintenance practices can also help maintain optimal flow conditions over time.

Friction Factor Determination

How do you accurately determine the friction factor to predict head loss in piping systems? First, identify the flow regime—laminar or turbulent—using the Reynolds number. For laminar flow (Re < 2000), the friction factor is straightforward: it’s calculated as 64 divided by Re. For turbulent flow, you’ll need to consult empirical formulas like the Colebrook-White equation, which accounts for pipe roughness and flow conditions. Vetted Properly selecting the right calculation method is essential for precise results.

Key points to remember:

- Use the Reynolds number to classify flow type

- Apply the appropriate formula based on flow regime

- Consider pipe roughness and fluid properties for accuracy

Calculating the friction factor precisely helps you predict head loss more reliably, ensuring ideal pipe sizing and flow management. Proper determination minimizes energy consumption and reduces wear on system components.

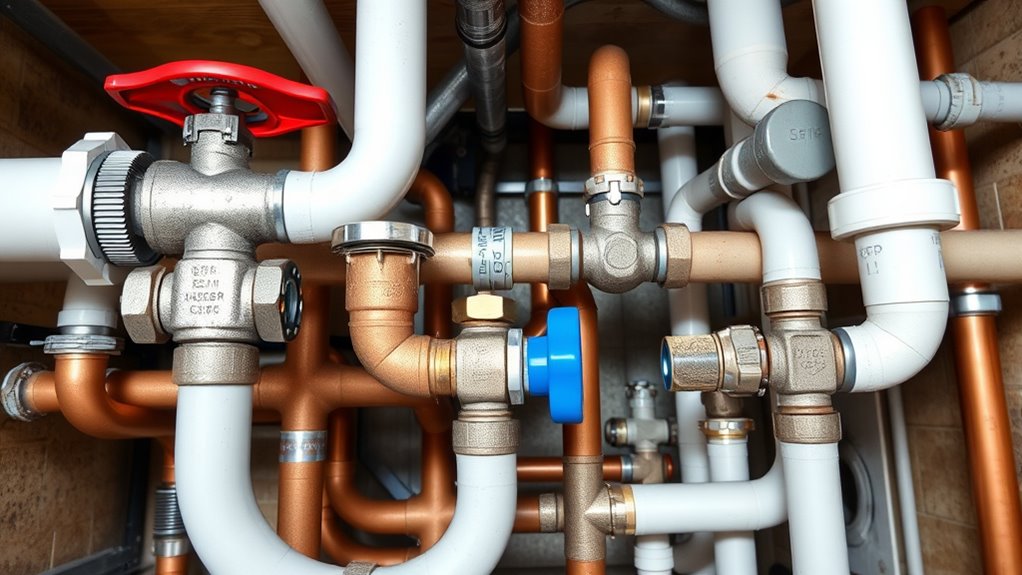

Pipe Material Impact

The type of pipe material considerably influences head loss in a piping system because different materials have varying surface textures and roughness levels. Smooth materials like copper or plastic reduce friction, resulting in lower head loss, while rougher materials like galvanized steel increase friction and energy loss. When selecting pipe material, consider how surface roughness impacts flow efficiency; smoother surfaces promote easier flow and better system performance. Additionally, material durability and compatibility with fluids matter, but head loss management hinges on surface characteristics. Knowing the roughness coefficient of your pipe material helps you accurately estimate head loss and optimize system design. Choosing the right material minimizes energy consumption, reduces pump work, and ensures consistent flow rates across the system.

Calculating Pressure Drop

Calculating pressure drop is key to understanding and managing head loss in a piping system. When you determine pressure loss accurately, you guarantee ideal flow rates and prevent system inefficiencies. To do this effectively, you need to consider factors like pipe length, diameter, fluid velocity, and roughness. Use the Darcy-Weisbach or Hazen-Williams equations to quantify head loss. Remember, small changes in pipe size or material can considerably impact pressure drop. Additionally, be aware that headphones can be used in some contexts to monitor audio signals in system diagnostics.

- Monitor flow velocity: High velocities increase head loss.

- Select appropriate pipe diameter: Larger diameters reduce pressure drop.

- Account for fittings and valves: These add to overall head loss, so include them in your calculations.

The Strategic Placement and Selection of Valves

Have you ever considered how the strategic placement and selection of valves can make or break your plumbing system’s efficiency? Properly placed valves allow you to control flow precisely, isolate sections for maintenance, and prevent pressure surges. When choosing valves, consider their size, type, and compatibility with your system’s material and pressure ratings. Placing shut-off valves near fixtures makes repairs easier, while balancing valves help maintain consistent flow. Avoid installing valves in tight or inaccessible spaces, which can hinder operation or maintenance. Use globe valves for precise flow control and ball valves for quick shut-off. Thoughtful placement minimizes unnecessary pressure drops and ensures system flexibility. Ultimately, selecting and positioning valves carefully enhances performance, reduces downtime, and prolongs your plumbing system’s lifespan. Recognizing the importance of fitting placement can further optimize system operation and maintenance efficiency.

Designing for Pressure Balance and System Reliability

To guarantee your system runs smoothly, you need to maintain pressure consistency across all components. Balancing flow rates prevents uneven wear and reduces the risk of failures. By designing with these points in mind, you can improve both pressure balance and overall system reliability. Incorporating appropriate valve selection techniques can further optimize flow control and system performance.

Maintaining Pressure Consistency

Ensuring consistent water pressure throughout the edge loop is essential for system reliability and performance. When pressure fluctuates, appliances may underperform, and pipe stress increases, risking leaks or damage. To maintain steady pressure, you should:

- Use appropriately sized pipes to minimize head loss and pressure drops.

- Install pressure regulators or balancing valves at strategic points.

- Regularly monitor system pressure and adjust valves as needed.

- Conduct periodic software quality assurance audits to identify potential issues that could affect system performance.

These steps help prevent pressure imbalances that could compromise the entire system. Proper pipe sizing reduces resistance, while regulators ensure uniform pressure across the loop. Consistent monitoring allows you to catch issues early and make adjustments before they escalate. By carefully designing for pressure consistency, you ensure the system operates smoothly, prolongs component life, and maintains reliable water delivery.

Balancing Flow Rates

Achieving balanced flow rates across your plumbing system is crucial for maintaining pressure consistency and ensuring reliable operation. To do this, you need to carefully select pipe sizes, ensuring they match the demand of each branch. Use flow restrictors or balancing valves to fine-tune flow in different parts of the system, preventing pressure drops or surges. Keep in mind that uneven flow can cause noise, leaks, or premature wear. Regularly monitor flow rates with flow meters to identify imbalances early. Adjust valves accordingly to distribute water evenly across fixtures. Proper balancing minimizes stress on pipes and valves, reduces energy consumption, and prolongs system lifespan. Focus on consistent flow distribution from the main line to each branch for ideal performance and system longevity. Additionally, understanding flow rates and head loss helps optimize system design and prevent pressure issues.

Preventing System Failures

Designing your plumbing system with pressure balance in mind is essential to prevent failures and guarantee long-term reliability. When pressure is uneven, pipes can burst, fittings may leak, and equipment can suffer damage. To ensure system stability, monitor pressure throughout the network and incorporate pressure regulators where needed. Regular maintenance helps identify early warning signs of failure before they escalate.

- Use appropriately sized pipes to reduce pressure fluctuations

- Install pressure relief valves to protect against overpressure

- Maintain consistent flow rates to avoid pressure imbalances

Common Challenges and Troubleshooting Techniques in Edge Loops

While working with edge loops, you’ll often encounter common challenges that can disrupt your modeling workflow. One frequent issue is non-manifold geometry, where edges connect improperly, causing rendering or animation problems. To troubleshoot this, check for overlapping vertices or hidden faces and clean up the mesh using merge or delete functions. Another challenge involves creating smooth, consistent loops; if loops are uneven or stretched, it can distort your model. Use edge slide or dissolve tools to refine the flow. Additionally, missing or extraneous edges can cause topology errors, so inspect your mesh carefully and remove unnecessary edges. Remember, maintaining clean, organized edge loops helps prevent future issues and simplifies adjustments, keeping your modeling process efficient and error-free. Proper topology ensures deformation and rendering are predictable and manageable.

Best Practices for Optimizing Piping Network Performance

Optimizing the performance of a piping network starts with ensuring your topology is clean and efficient. You want a layout that minimizes unnecessary bends, loops, and long runs, which can increase head loss. Proper pipe sizing is vital; use the right diameter to balance flow rate and pressure loss. Regularly inspect valves and fittings to prevent obstructions and leaks that reduce efficiency. Incorporating high-quality projectors can also help visualize flow and pressure data for better system analysis.

To maximize performance:

- Maintain consistent pipe diameters where possible to avoid turbulence.

- Keep pipe runs as straight and direct as you can.

- Regularly monitor pressure and flow rates, adjusting as needed.

Implementing these practices helps reduce energy costs, prolongs equipment life, and guarantees reliable operation of your piping system.

Frequently Asked Questions

How Does Pipe Material Affect Flow and Pressure Drops?

Pipe material directly impacts flow and pressure drops because different materials have varying roughness levels. For example, smooth materials like copper or plastic reduce friction, maintaining better pressure and flow, while rougher materials like galvanized steel cause more friction, leading to higher pressure drops. You should select pipe materials based on your system’s flow requirements and pressure needs, ensuring efficient operation and minimizing energy costs.

What Are the Latest Technological Advancements in Valve Design?

You’ll find that smart valves now incorporate IoT technology, allowing remote monitoring and control. For example, a recent case study shows a smart valve system reducing water waste in a commercial building by 30%, thanks to real-time leak detection and automatic shutoff. These advancements enhance efficiency, reduce maintenance, and improve system responsiveness, making them essential for modern plumbing systems that demand precision and adaptability.

How Can System Noise Be Minimized in Complex Piping Networks?

To minimize system noise in complex piping networks, you should start by selecting silencers or mufflers designed for your system’s specific flow. Use flexible connections and proper insulation to absorb vibrations. Maintain appropriate pipe sizes to prevent turbulence, and install valves carefully to avoid water hammer. Regular maintenance and balancing flow rates also help reduce noise, ensuring quieter operation and extending the lifespan of your piping system.

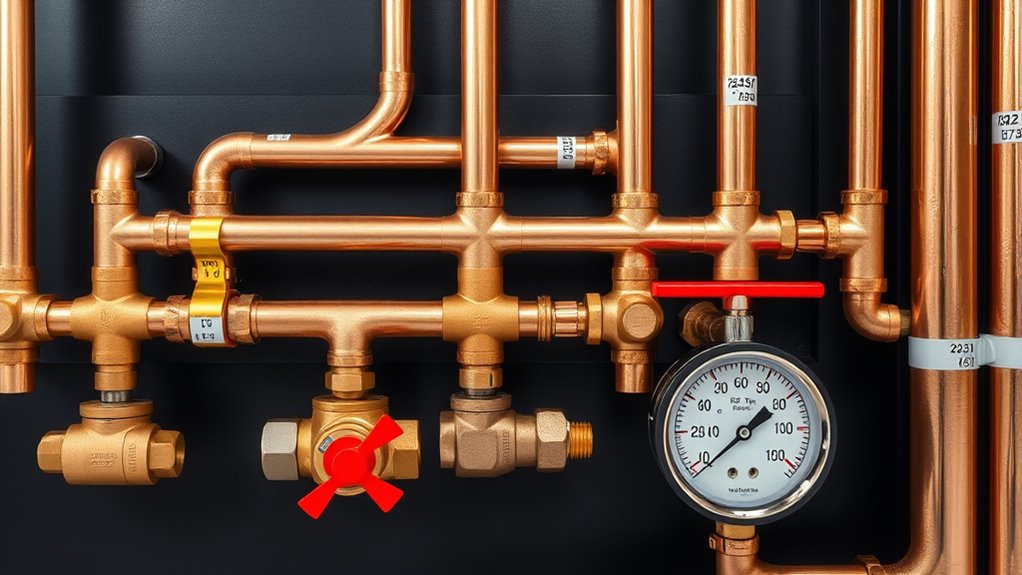

What Safety Considerations Are Critical for High-Pressure Edge Loops?

You must prioritize safety by ensuring your high-pressure edge loops have proper pressure relief valves installed to prevent over-pressurization. Regularly inspect and maintain these valves, use appropriate pipe materials rated for high pressure, and incorporate pressure gauges for continuous monitoring. Additionally, educate all personnel on safety protocols, and design the system with accessible shut-off valves to quickly isolate sections if needed, minimizing risk of accidents or damage.

How Does Environmental Impact Influence Pipe Sizing Decisions?

You realize environmental impact is a game-changer in pipe sizing decisions. By choosing eco-friendly materials and optimizing pipe diameters, you drastically reduce resource consumption and pollution. Smaller, efficient pipes cut energy use and greenhouse gas emissions, making your project a hero for the planet. You prioritize sustainable choices, knowing your decisions ripple outward, conserving water, lowering waste, and protecting ecosystems for future generations.

Conclusion

Believe it or not, optimizing your edge loop isn’t just about pipe sizes and valves—it’s about trusting that a well-designed system can prevent headaches and save you money. Many think complexity breeds failure, but with careful planning and understanding, you can achieve reliable, efficient plumbing. Don’t underestimate the power of proper design; it truly makes all the difference. When you get it right, you’ll feel confident knowing your system performs flawlessly every time.