To keep air out of the edge circuit effectively, place filters near the air intake points, focusing on areas where dust and contaminants tend to enter. Position filters upstream of sensitive components and align them with natural airflow paths to prevent dirt buildup and airflow restrictions. Regularly monitor and replace filters to guarantee peak performance. For detailed strategies that help protect your system and extend its lifespan, explore the upcoming insights.

Key Takeaways

- Place filters close to the air intake point to prevent dust and contaminants from entering the edge circuit.

- Position filters upstream of sensitive components to block pollutants before they reach critical areas.

- Ensure filters are aligned with natural airflow paths to maximize dust capture and airflow efficiency.

- Regularly check and replace filters to prevent clogging, which can force air into undesired circuit areas.

- Incorporate sensor feedback to optimize filter placement and maintain effective air exclusion from the edge circuit.

Understanding the Importance of Proper Filter Placement

Proper filter placement is crucial because it directly impacts the efficiency and longevity of your filtration system. When filters are correctly positioned, they effectively trap dust, debris, and contaminants before they reach sensitive components. Incorrect placement can cause airflow restrictions, reducing system performance and increasing energy consumption. It may also lead to frequent filter replacements, costing you more in the long run. Proper placement ensures the filter captures pollutants at the ideal point, maintaining airflow and system health. You want to prevent dirt buildup on other parts of the system, which could cause damage or malfunction. Additionally, understanding Chevrolet Tuning techniques can help optimize your vehicle’s air intake system for better performance. By understanding where and how to position your filters correctly, you improve air quality and extend your system’s lifespan. Taking the time to properly install filters pays off with better performance and fewer maintenance issues.

Identifying Critical Areas for Filter Installation

To maximize your filtration system’s effectiveness, you need to identify the most critical areas for filter installation. Focus on spots where dust, debris, or contaminants tend to accumulate or enter. Typically, these include air intake points, corners, and high-traffic zones. By targeting these areas, you prevent pollutants from spreading throughout your system. Additionally, understanding eye patch benefits can help you appreciate how targeted interventions improve overall system performance.

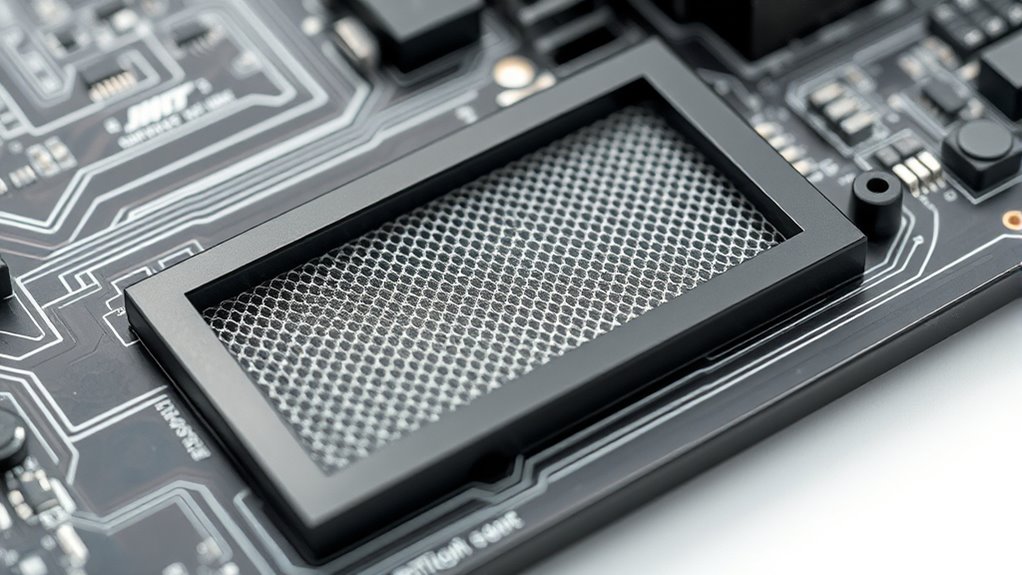

Selecting the Right Filter Types for Edge Circuits

Choosing the right filter type for edge circuits is crucial to guarantee peak performance and longevity. You need to evaluate the specific contaminants present and the environment in which your circuit operates. For dust-heavy areas, a high-efficiency particulate air (HEPA) or fine mesh filter can effectively trap small particles. If moisture or humidity is a concern, opt for filters with moisture-resistant properties to prevent mold and corrosion. For chemical vapors or gases, activated carbon filters are essential. Additionally, consider the filter’s airflow resistance; a filter that restricts airflow too much can impair circuit performance. Balance filtration efficiency with minimal pressure drop to ensure your system remains ideal. Selecting an appropriate filter type tailored to your environment helps protect your edge circuits and extends their service life. Understanding Bitcoin IRA strategies can also inform maintenance and protection approaches for sensitive electronic components.

Strategies for Effective Filter Positioning

Strategically positioning filters is essential to maximize their effectiveness and protect your edge circuits. You should place filters as close to the source of potential contaminants as possible, preventing dirt or debris from entering sensitive components. Positioning them upstream ensures that particles are captured early, reducing the risk of damage downstream. It’s also important to contemplate airflow paths; place filters where airflow naturally converges or where your system’s pressure is highest to optimize filtration efficiency. Avoid placing filters in areas with restricted access or where they might cause airflow bottlenecks. Regularly inspecting and maintaining filter positions ensures continued protection. Additionally, understanding the importance of airflow management can help you select optimal filter locations that enhance system performance. By carefully selecting locations that maximize contact with incoming air and minimize bypass risks, you enhance overall system reliability and extend the lifespan of your edge circuits.

Common Mistakes to Avoid When Placing Filters

When placing filters, you need to avoid common mistakes that can diminish their effectiveness. Improper placement, ignoring airflow balance, and neglecting maintenance can all cause issues. Being aware of these pitfalls helps ensure your system runs smoothly and efficiently. Additionally, ensuring proper alignment of the filter placement with your system’s airflow path can prevent unnecessary strain on components and improve overall performance.

Avoiding Improper Filter Placement

Proper filter placement is essential to guarantee ideal system performance and prevent damage, but many common mistakes can compromise these goals. To avoid issues, ensure filters are installed in the correct location, not too close to sensitive components or airflow obstructions. Misplacing filters can cause uneven airflow, reducing efficiency and risking component wear. Also, avoid installing filters that are incompatible with your system’s specifications, as this hampers filtration effectiveness. Proper sealing is critical; gaps can allow unfiltered air to bypass the filter, defeating its purpose. Finally, don’t neglect regular maintenance—clogged filters increase pressure drops and strain the system. Regularly consulting filter specifications helps ensure compatibility and optimal performance.

Neglecting Airflow Balance

Neglecting airflow balance during filter placement can lead to significant system inefficiencies and potential damage. When airflow isn’t properly managed, you risk creating high-pressure zones or restricting airflow, which strains your equipment. Poor airflow causes uneven filtering, allowing contaminants to bypass filters or accumulate in certain areas. This imbalance can decrease overall system performance and increase energy consumption. To avoid this, ensure filters are positioned where airflow is steady and evenly distributed. Use airflow measurement tools to verify balance before final installation. Proper placement maintains consistent airflow rates and prevents undue stress on fans and ducts. Additionally, understanding industry trends can help you adapt your setup for optimal performance. Remember, a well-balanced airflow system not only improves filter effectiveness but also prolongs equipment lifespan, saving you money in the long run.

Overlooking Maintenance Intervals

Overlooking maintenance intervals is a common mistake that can undermine your filter placement efforts. If you don’t track when filters need replacing, you risk airflow restrictions, equipment strain, and reduced efficiency. Regular maintenance ensures filters perform at their best and prolongs their lifespan. Failing to adhere to recommended schedules can lead to dust buildup, clogging, and compromised air quality. Additionally, incorporating evidence‑based practices into your maintenance routine helps ensure optimal filter performance and system longevity. To avoid this, keep these points in mind: – Establish a clear maintenance schedule based on manufacturer guidelines – Monitor filter condition regularly for signs of dirt accumulation – Use maintenance logs to track replacement dates – Educate staff on the importance of timely filter changes – Adjust intervals for different environments or usage levels

Consistent upkeep maintains airflow and protects your system’s integrity.

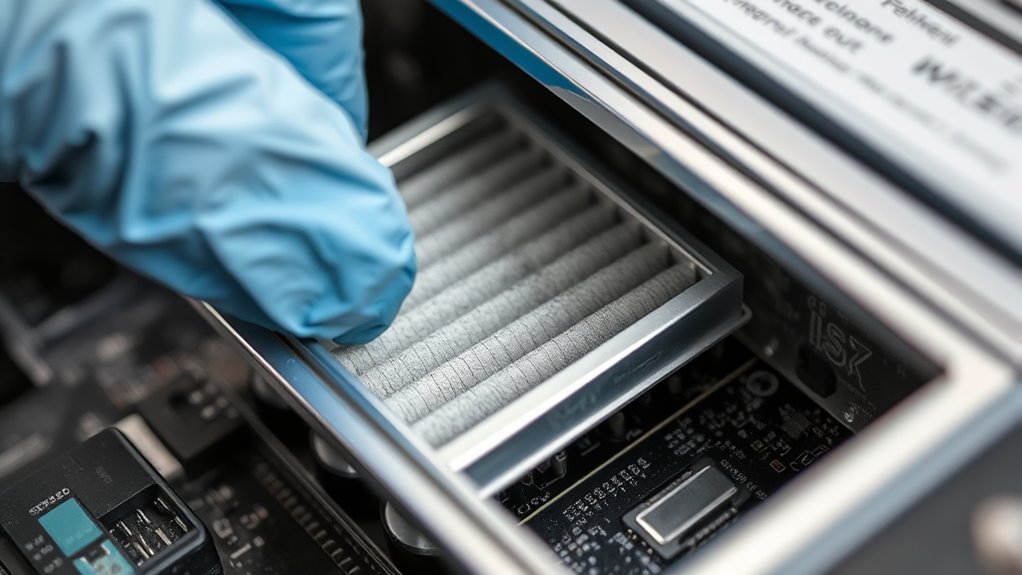

Maintenance and Monitoring of Filtering Systems

Regular maintenance and monitoring are essential to guarantee your filtering systems operate effectively over time. You should regularly inspect filters for dirt, damage, or clogging, and replace or clean them as needed to maintain airflow and filtration quality. Monitoring system performance helps you identify issues early, such as decreased airflow or increased pressure drops, which signal that filters need attention. Keep a detailed maintenance schedule and track filter lifespan to prevent unexpected failures. Use sensors or gauges where possible to monitor system parameters continuously. Always follow manufacturer guidelines for cleaning and replacement intervals. Incorporating filter lifespan tracking can further enhance your maintenance routine. Consistent upkeep ensures your filters perform at their best, prolongs their lifespan, and maintains air quality. Staying proactive in maintenance prevents costly repairs and keeps your system running smoothly.

Case Studies Demonstrating Successful Filter Placement

Examining real-world examples reveals how effective placement strategies can improve filtration outcomes. These case studies highlight practical solutions and the impact of well-planned filter locations. By exploring these successes, you can better understand what works in different environments. Additionally, understanding asset division laws and strategies can ensure a more equitable outcome in divorce proceedings.

Effective Placement Strategies

When selecting ideal locations for filter placement, case studies reveal that strategic positioning can considerably enhance filtration efficiency and system longevity. You should prioritize high-traffic or high-contamination zones to intercept pollutants early. Placing filters upstream of sensitive components prevents buildup and reduces maintenance needs. Consider airflow patterns to ensure even distribution and avoid dead zones where contaminants may accumulate. Regularly assess and adjust filter positions based on system performance data. Properly positioned filters not only improve air quality but also extend the life of your equipment.

- Prioritize high-traffic areas for initial filtering

- Position upstream of sensitive components

- Align filters with natural airflow patterns

- Incorporate sensor feedback for optimal placement

- Ensure easy access for maintenance

Real-World Implementation Examples

Have you ever wondered how strategic filter placement makes a real difference in operational efficiency? In a manufacturing plant, installing filters at the air intake minimized contamination, reducing equipment downtime by 30%. Similarly, data centers that position air filters near critical components prevent overheating and cut maintenance costs. In a hospital’s HVAC system, strategically placed filters improved air quality, lowering infection risks. These examples show that understanding airflow patterns and identifying high-risk zones lead to successful filter deployment. When you target key points where contaminants are most likely to enter or accumulate, you enhance system performance and longevity. Real-world cases prove that thoughtful filter placement isn’t just theoretical—it’s essential for optimizing operations and safeguarding assets.

Frequently Asked Questions

How Does Filter Placement Impact Overall Circuit Longevity?

Proper filter placement directly impacts your circuit’s longevity by preventing dust, debris, and moisture from reaching sensitive components. When you position filters correctly, you reduce the risk of overheating, corrosion, and electrical failures. This keeps your circuit cleaner and more efficient over time. You should regularly check and replace filters to guarantee ideal airflow and protection, ultimately extending the lifespan of your entire circuit system.

Can Improper Filter Positioning Cause System Overheating?

Yes, improper filter placement can cause your system to overheat, like trapping a heatwave inside a closed room. When filters aren’t correctly positioned, dust and debris block airflow, forcing components to work harder and generate more heat. This buildup can lead to overheating, risking damage and system failure. Always make certain filters are installed properly, allowing cool air to flow freely and keep your system running smoothly and cool.

What Are Cost-Effective Methods for Improving Filter Placement?

To improve filter placement cost-effectively, you should guarantee the filter fits snugly in its designated slot, preventing air bypass. Regularly inspect and replace filters to maintain efficiency. Use affordable sealing methods like weatherstripping around the filter edges to block unwanted air leaks. Additionally, follow manufacturer guidelines for proper positioning to maximize airflow and avoid system strain, all without significant extra costs.

How Do Environmental Factors Influence Filter Effectiveness?

Environmental factors substantially influence your filter’s effectiveness. Dust, humidity, and airborne pollutants can clog or degrade filters faster, reducing their ability to trap contaminants. High humidity encourages mold growth, while dust and debris can block airflow. You should regularly check and replace filters in dusty or humid environments, and install filters suited to your specific conditions. Proper maintenance guarantees ideal filtration and prolongs your system’s life.

Are There Industry Standards for Filter Placement in Edge Circuits?

Yes, industry standards guide filter placement in edge circuits to guarantee ideal performance. For instance, a tech company in Silicon Valley placed filters right at the circuit’s edge, preventing dust and moisture from entering sensitive components. This setup improved reliability and extended equipment lifespan. You should follow standards like IEEE or IEC, which recommend positioning filters close to critical components to maximize their protective benefits.

Conclusion

Think of your filter placement as tending a garden—each careful choice keeps pests out and helps your edge circuit flourish. When you position filters correctly, you’re nurturing a healthy, efficient system that resists contamination. Avoid common mistakes and stay vigilant with maintenance, so your efforts don’t go to waste. Remember, a well-placed filter acts like a sturdy fence around your garden, protecting it from unwanted intruders and allowing your system to thrive.